Not All Whistles Are Created Equal!

Most whistles that can be found in the typical band instrument music store are very inexpensive and are sometimes less than perfect. (No really!) Having purchased many inexpensive whistles has provided me with the opportunity to make improvements to the instruments without a serious risk of ruining a high-dollar investment. Here are several modifications and improvements which you, yes YOU, can perform to tune and improve the tone of your whistle.

~

When you listen to a player making beautiful notes on what appears to be a typical whistle, know that it is not magic. The whistle was made exceptionally well through the mass-production process or it was improved by someone who cares about the sound. Some musicians prefer a less than perfect sound from their whistle but marketed recordings more often have very good players and instruments in their makeup. You can have a good sounding instrument by 1. Getting lucky, 2. Vetting the potential whistles until you find a good one, 3. Making your whistle bend to your will to become a happy whistle player and modify it. If you are worried that you may break your whistle in the process, it is fair to let you know that this is possible. Things can go from bad to worse but more likely, you will make a valuable improvement to your whistle and become a happier whistle player.

Clark Conical Bore Mods (Wood Plug)

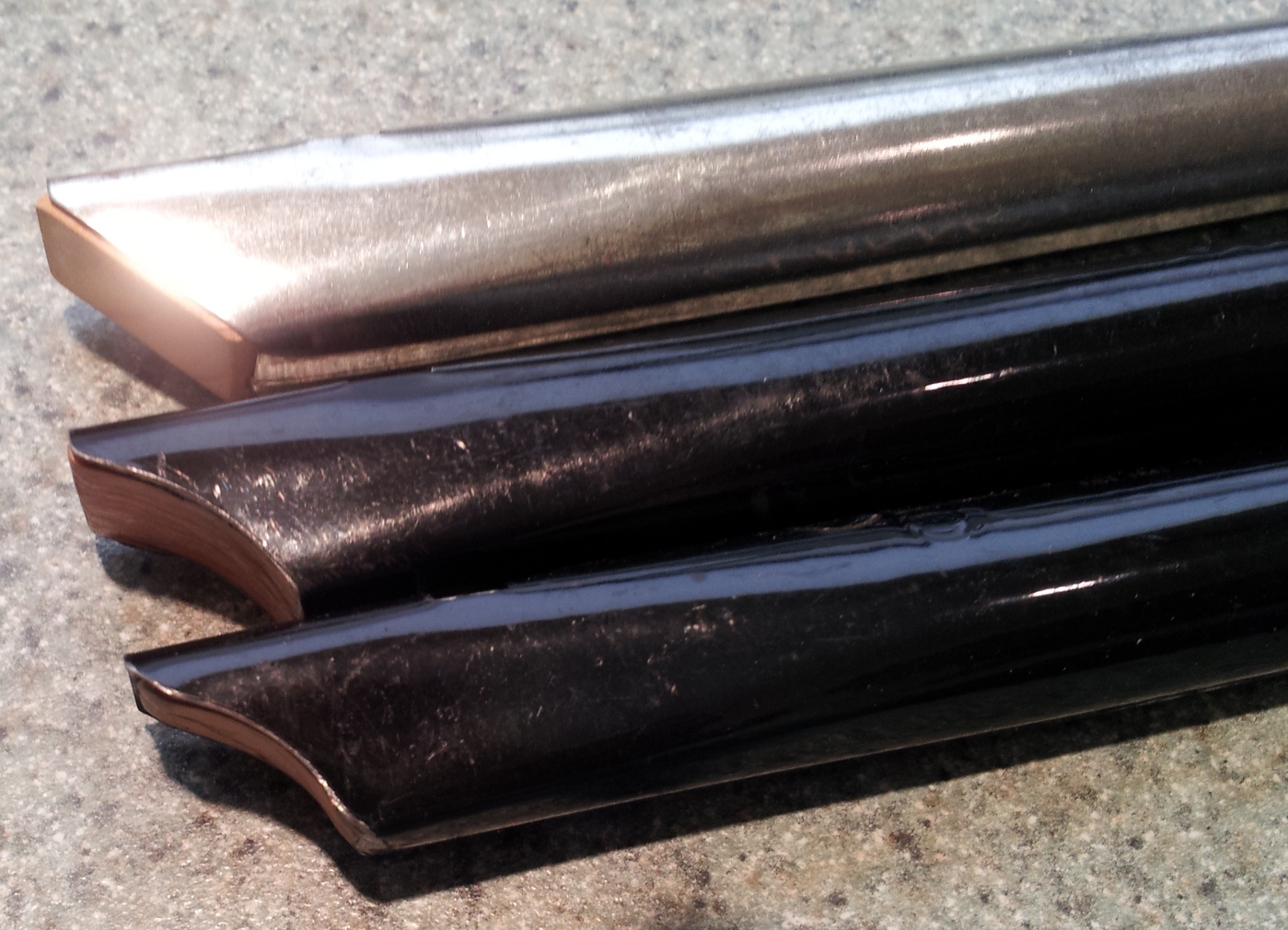

These mods address issues with the Classic black with diamonds. It is also applicable to other whistles with similar designs. The whistle may be too breathy, taking too much air to play or making a poor tone. These mods will help you improve what is otherwise a fine instrument. Below is a Clark whistle in its bare tin plate and also shown in black. Note how the wood plug is sticking out from the metal? This is an indication that the plug was not correctly set during construction. The wood should be flush with the end of the pipe and should also be flush with the inside edge of the windway. Deviations from this can make the whistle sound poor and make it uncomfortable in your mouth as well. After setting the wood plug correctly at the inside edge of the windway, I sanded the outside of the plug and metal tube to be a very comfortable and shapely design. I also used clear laquer to seal the wood surface and the joint between the wood plug and metal tube.

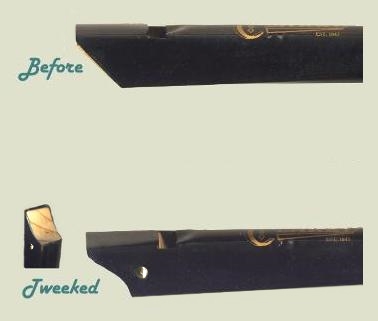

This modification can improve the tone and reduce the breath requirements of the Clark whistle. It involves reshaping the metal tube where it crowns over the wood plug to form the windway. The original windway has a high-crowned shape which makes for a vey open and wasteful passage for the airflow. The tube section which makes the windway around the wood plug can easily be modified to reduce the air requirement and improve the purity of the tone. Do this after ensuring that the inside end of the wood plug is flush with the inside end of the windway.

~

Press the metal tube area over the wood plug to compress it towards the plug. This will deform the sidewalls of the tube where it wraps around the plug. It is natural for this to occur. I do not know of a mathmatical formula to provide but by carefully and progressivly compressing and testing the tone produced, you will learn how far this modification can go. If you compress the tube past the desired point, simply insert a metal or plastic object such as a narrow butter knife or a small, flat screwdriver between the wood plug and the metal tube of the windway to lift it back up a bit. The inserted object should be at least 1mm wide. Often, a simple round or flat toothpick will work if nothing else is available.

When testing the results of the flatening of the windway, be sure that you hold the mouthpiece with your lips completely sealing around the end of the whistle. This is necessary to prevent air leaking around the plug. Once you are sastisfied with the tone, use a clear laquer or nail polish to seal the joint between the tube and the wood plug. Allow the laquer to dry completely before playing. Several coats may be required to completely fill he gap. The example shown appears to be incompletely filled. The laquer may shrink into the resesses and need another coat once it is dry. If the end joints are not sealed, air will leak around the plug and create irregular tone quality.

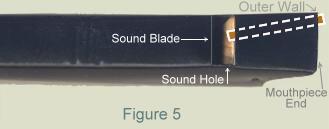

This modifcation also addresses the shape of the windway to reduce air requirements but may not improve the breathiness of the tone. It will reduce the potential volume that the whistle can produce. If you desire to make your Clark whistle more quiet, this mod is for you! It is easy to perform and usually has good results. A toothpick or other wood product is inserted into the windway to funnel the air to one side of the sound blade. The inserted object must be shaped and cut to length so as to not stick out of the windway at either end.

~

Note: These modifications can be performed by most people who can work carefully with small objects. However, if you are not comfortable doing this work, the modifications are available as a paid service of The Whistle Shop.com

~